Long Term (Vehicle) Relationships

~ Friday, February 24, 2006 ~

(Posted to a local email group in February 2006) A few days ago I reached another one of the Mileage Milestones

on my 89 Plymouth Voyager, which got me to thinking about when it would be time to move on to my next vehicle, and about my long term relationships with past and present vehicles in general (I think a lot of female readers just went on to the next email - hey, it’s a Guy Thing).

I was one of those kids who took everything apart to figure out how it worked. Reassembly success was spotty, especially in the younger years. We had a Sears two-wheeled “garden tractor” with a big old Briggs and Stratton single cylinder engine on it. It, too, succumbed to my youthful wrenchings, and I was fascinated to discover all the shiny parts inside that made it go. I even managed to get it put back together again. The first time I pulled the starter rope and it went chuff!-pop-chug-chug-chug… well, I’ll never know what it is like for a woman to grow a baby in her body and deliver it to life - but for a young guy that was probably about as close as he’ll ever get. Going from a collection of oily pieces of metal to a running engine - Wow! - brain surgeons had nothing on me! I found the whole thing so thrilling I pulled that engine apart a number of times, every time learning more about what each part did and how they all worked together.

My stepfather had a Gulf Service Center (you did not call it a “gas station” unless you were in the mood for a long and boring lecture). When I was in high school and had my first old clunker (1952 Plymouth) I’d go down to the station (in DC) and use the lift, tools and service manuals at night.

One night I decided to see what was in my transmission (I knew how to have fun!) There was a full set of Motor’s Auto Repair Manuals there, so what could go wrong? With the car up on the lift it was easy to drop the transmission and it came apart pretty quickly. After I had satisfied my curiosity about the innards I was starting to put it back together, reading the pages of the manual as I went. I came to the part about setting a big cluster gear in the case, although first I was supposed to put in a “dummy shaft” to hold about 30 or 50 little needle bearings in place. I looked all over the parts blowups trying to figure out which was the “dummy shaft”. I should have been looking in a mirror.

It was a “special tool”, and I did not have one. At that point the clock started going faster (I had to be out of there by the time the mechanics came to work), and it was seeming like a little less fun. The problem was to hold all of those tiny bearings in place while assembling the transmission. If I had had the tool, it would have held the bearings in place until the real shaft was inserted. As it was I was packing all those needles in grease and *very* gently moving things around, trying not to knock any of them loose. I think it took a few hours, but I finally got it. Lesson learned: read *all* the way through a procedure - including the putting-it-back-together part - before taking it apart.

One of my first ambitions in life had been to be a Mechanic (I don’t think I even knew what an Engineer was at that time, unless it was a guy in a striped hat that drove a train). As I pursued that goal, it did not take me long to figure out that, while putting in the first water pump might be really interesting, by the time you had put in the exact same type pump several times, the thrill was gone. It was many years later before I discovered Engineering, but when I finally did it was like the old John Denver song about “coming home to a place he’d never been before”. All those years I had been baffled about how somebody knew to make a connecting rod just that size, or myriad other details about the design of anything complex. How did they know to make it so it would work, but not break? In my first engineering classes it was like somebody was showing me a magical toolbox with all these wonderful shiny tools that would answer all the questions I’d ever had. I was immediately hooked.

But back to vehicles. Although I abandoned being a mechanic as a career goal, I did not lose my interest in tinkering with engines and anything mechanical. So my own vehicles (cars and motorcycles) became a natural focus for rooting around in things mechanical. Over the years I developed the philosophy that I would “do it myself” - even if I’d never done something before, and did not have the tools needed. The manuals are readily available, and if Fred down at the garage can learn to do it, well, then I ought to be able to as well. And often it would have been cheaper to hire a job out than to buy the tools needed to do it, but over time, as I collected more tools, that situation quickly reversed itself.

Sure, there were some frustrating episodes and downright bungles, but every one of them was an education. And whenever I would do a major job, like rebuilding an engine, I would again have that thrill of “giving birth” when it would fire up for the first time. And for a few days or weeks, while the mental images were still fresh, I would be able to drive down the road and visualize exactly how all those parts I had recently held in my hands were moving in relation to each other.

I think many people are scared off by modern vehicles - one look at all those belts and hoses under the hood and they are intimidated. Engines today are the same as they were 100 years ago - not that much has really changed, except they are a lot more reliable. And in many ways they have gotten much simpler. Take a carburetor for example. These could be horrendously complicated contraptions, full of multiple tiny passages, orifices, valves, springs, metering jets, dashpots and pumps. Engine conditions vary widely, from high speed, light throttle to wide open throttle at low engine speeds, and any combination in between, and each would require a special setting to achieve the right fuel mixture to keep the engine running smoothly. All this had to be accomplished mechanically, based on a relatively few inputs. The result was often a very complex contraption that would have made Rube Goldberg proud. Today’s fuel injection, by comparison, is very simple. A fuel pump pressurizes a fuel line, and the injectors are simply electrically operated valves that open and close at the direction of the computer. The computer monitors a great many things, including the burned gases from the last cycle, and calculates a precise timing for the valve to open to get exactly the right amount of fuel for that cylinder on that stroke. It’s like having a racing mechanic living under your hood, instantaneously tuning the engine to every condition that occurs. And that extremely complex carb is replaced by a pump and some valves and a computer. Sure, computers die, but not very often, and then you simply plug in another one.

Computerized engines often simplify much of diagnosis - quite often they can tell you, through “fault codes” what is ailing them. Sometimes they get it right, sometimes they don’t, but quite often they at least get you pointed in the direction of a problem. But they miss a lot too. And one of my biggest complaints about modern vehicles is the service manuals. Back in the Old Days service manuals actually gave you useful information, as did most “owner’s manuals”. I can still remember buying appliances or tools that came with parts diagrams and lists, repair procedures, and all sorts of useful information. If you can recall those, you’re an Old Fart too! Today’s “manuals” are nothing but useless safety warnings (”don’t put the camera strap around your neck - you could strangle” - and that’s a real warning from my Nikon manual!) Maybe, on the last page or two, there might be some marginally useful information, but often this is just an instruction to call (non-existent) “tech support” for anything that resembles a real question. My previous vehicle, a 1978 Datsun pickup, had a very useful manual. For each section there would be a couple of pages at the beginning explaining the “theory of operation” - often the most useful part of the whole book. These would be brief, but useful, explanations of what each part in the particular system did and how they worked together. Many times it would be this section, not the trouble-shooting charts later on, that would provide the real keys to solving your problem. Today’s manuals go more like this: insert the Framistat tester lead ‘C’ in port J while reading the voltage across pins B and C. If below xxx replace Whatzit B. No clue as to what the voltage represents, what the Whatzit is for, or what the Framistat tester is reading.

Sometimes those procedures will find a problem and allow you to fix it, but without giving you much insight. To gain the insight part you pretty much have to figure out on your own, from whatever clues are available, how it is/was supposed to work. Because once the manual procedures fail to find the problem that is all you have left to go on. I’ve had some things that have taken an awful long time to finally sort out, even years in some cases. But that is one of the really fascinating things about taking vehicles to high mileages - you have time to figure out how they really work, and how they fail. You can even save a lot of money over buying and trading in almost-new vehicles. There are drawbacks, of course. You don’t always get where you are going when you had planned to. My van is full of tools and spare parts. Sometimes I even have the right spare part when something quits, although mostly I just have extra ballast for the snowy days.

I’ve learned much from each vehicle with which I have had a long term relationship. My 89 van was the first with a computer, which was fascinating to discover. Some problems of older vehicles vanished with this new technology, but others were brand new. Here are a few of the ‘learning experiences’ I have had with this vehicle:

The Knock Sensor

I started noticing the engine running much rougher, and the gas mileage was going down. The computer thought everything was fine. I even looked at the data streams and everything looked fine (temperatures, pressures, O2, etc). Ignition system seemed fine. Finally I noticed that, when not idling, but driving down the road, that the spark timing for each cylinder was wildly erratic, often being retarded by 20 degrees or more. While away on vacation I finally identified the problem as the knock sensor. This is basically an accelerometer that detects ‘detonation’ (pinging) in any cylinder, and immediately retards the spark timing to that cylinder until the detonation stops. So I called around the various auto parts places and inquired if they had a Knock Sensor. Most said no. One finally said, “a what?” - “knock sensor” -” … long pause - yeah, I got one”. So I drove nearly 30 miles to go get it. He pulls out an Oxygen sensor. No, I wanted a knock sensor. What’s that? Grrrrr. Eventually I got one from a dealer ($$$). Problem solved. Or so I thought. Then I discovered that there seemed to be a bad connection at a plug connector in the wiring harness. Fixed that. Problem solved. Not. After a couple more months of fiddling with an on and off again problem, I finally discovered that moving the wiring harness near the computer could cause the problem to occur, or stop. Even later after that I finally convinced myself to rip open the wiring harness and trace out that particular wire. Sure enough, there was a damaged spot in the wire from clear back when it had been made. That really did solve the problem. Head Scratching 1 - computer 0, for that one.

Fuel System Saga

OK, I know I just told you how simple a fuel injection system is. It really is. But that still doesn’t mean it can’t have problems. First of all, here is how it works (most of this I had to figure out on my own, and if I’d known then what I know now I could have solved my problems very easily): a fuel pump sits *in* the gas tank (submerged in the gasoline). It pumps out gas at a fixed flow rate at fairly high pressure (>50 psi) up to the “injector rail”, which feeds the fuel injectors. A pressure regulator bleeds off any fuel not needed which travels back to the tank. Thus there is a continuous flow of pressurized gas at the entrance to each injector. To “inject” fuel the injector/switch simply turns on and the pressurized fuel flows into the intake manifold. Now, fuel at high pressure could be a pretty dangerous thing if you develop a leak. So they have some safety features built in. One of them is that the fuel pump will only run for a couple of seconds if there is no engine spark detected. This is for, say, being in an accident where a fuel line is ruptured. If the engine is not running, the fuel pump is shut down and the fire hazard is reduced. That’s pretty much the extent of the fuel delivery system, except for a filter and a few other odds and ends.

One of the long standing problems I had had ever since I bought the van was difficulty hot starting. It would crank for a long time before starting. I finally found out I could avoid the cranking by simply turning the key on and off a couple of times before starting - then it would fire right up. It was a puzzle, but I had a simple work around so I did not spend much time thinking about it.

During one routine service procedure I was following the manual instructions to bleed the pressure from the fuel rail before disconnecting a line. There was no pressure to bleed. From that I learned two things: there must be a check valve in the system that would maintain the pressure, and mine was not working. Well, the only time I could see that I needed pressure was when the engine was running, and then the pump maintained pressure, so it seemed pretty useless and I thought little more of it.

Then my fuel pump died, but slowly, during a drive to DC. The engine was running very erratically, and a pressure gage on the fuel rail showed the pressure was way low. I managed to get it back home, although I went up some of the hills on I-81 at 30 mph. I bought an after-market fuel pump, dropped the gas tank, and pulled out the old fuel pump. Geez - they just wanted you to cut the leads on the pump and crimp in the leads for the new one. This did not seem at all like a good idea to me - what if that connection sparked in the tank?? I once drove gasoline tankers - I had seen what a spark in an *empty* tank could do (can you say “Bomb”?) But I didn’t see much way around it, so I did it. And all went well - for a few months or a year, when it quit again.

#$#%$*# After Market Crap!!! This time I went to the dealer and paid the $$$$ to get the OEM part. Instead of just the pump, they sold the whole assembly that fits into the top of the tank as a single unit. This included the non-functioning check valve that I did not think I needed. Guess what - no more hot start problem!! And then I realized what that check valve was for - to maintain pressure and prevent vapor lock when a hot engine was shut off! Without the check valve the fuel rail would get hot, the gas would boil, and I’d have a rail full of vapor. It would take some time of the pump running to flush out the vapor, which was why it would crank for so long. Every time I turned the key on, without cranking, the pump would run for about a second before the safety switch would shut it off. Doing this several times, without cranking, would flush the vapor without the long cranking session. It was hard won knowledge, but you can bet I’ll never forget it.

The pump quit a third time!! And this was my NEW Dealer pump!!! It always seemed to quit when I had a full tank of gas, which had to be siphoned out before I could drop the tank. So I really took a close look at things, because this was getting old. I finally discovered the problem - the electrical connector to the top of the tank is encased in a large rubber boot to seal things. On close inspection it became apparent that the blade on one of the connections was sliding alongside the mating piece, not inside as it should have been. And it looked like it had come from the factory like that, and it had gone back together like that every time. And there was simply no way to know for sure whether you had it connected correctly or not - the large sealing area prevented seeing what was going on inside. It was quite likely that the first pump had been OK when I replaced it. I finally solved my problem by bypassing the connector altogether and soldering the leads on. That has been working fine ever since.

After Market Crap

It took me a long time to learn, but more and more often I now go to the dealer, cough up the extra $$$, and get the OEM part. Especially if it is a critical or hard to replace part. Sure, it’s great that AutoCrap has a lifetime warranty on their parts. It’s a real comfort to know that they’ll replace your $15 widget for free - after you do $500 of labor to get it out. My most recent bitter experience on that was with the clutch on the van. At 200k miles I had a differential carrier bearing on the transaxle that needed to be replaced.

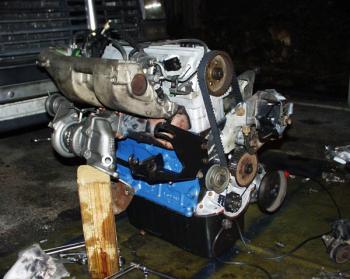

While I had it out I replaced all the transmission bearings and the clutch too. I put the new AutoCrap clutch next to the original one, and I could not tell any difference in the thickness of the linings, there was hardly any wear in that clutch after 200k. The flywheel was only lightly scored, but I had it machined anyway. I put it all back together and the new clutch worked smooth as silk. For about 5 miles. Then I pushed in the pedal to shift and I felt something happen. Not sure what, but it was different. I never could get the clutch to engage without chattering after that. I was convinced a spring had broken or something similar. At 328,000 miles the clutch was starting to slip (only 128k on the new clutch), and I was thinking it was time to take a look inside the engine anyhow, since it had never been apart. I found that the clutch linings were worn down to bare metal, the pressure plate was nearly destroyed, and the flywheel was so deeply worn that the machine shop guy was not sure he could salvage it. I never did find the broken part(s) I was convinced would be there, so what happened is still a mystery to me. But I went straight to the dealer and happily pad 2 or 3x the AutoCrap price for their clutch. With 115k on that clutch it is still smooth as silk, and I doubt there is much wear.

So now I find myself considering moving on to a new relationship. I had originally wanted to go to 500k on this one, and maybe I still will. But there has been an awful lot going on with computers and new technology in the 17 years since this van was built, and I’d like to get my hands on some of the newer stuff to start learning about it. At some point, maybe soon, maybe not, I will be driving along a used car lot and that Special Someone will catch my eye and I’ll know that is the One. In the meantime, I’ve still got some things I haven’t figured out on this Old Friend.

I never quite made it to 500k miles.

At 498k (in 2008) it started running rough, and I initially interpreted it as a blown head gasket. I parked it to work on it later and bought a replacement vehicle. By 2010 I knew I was never going to get around to it, but wanted to find it a good home, as it was a very unique vehicle: a factory stock Minivan with a turbocharger and 5-speed manual transmission - it was fast! I checked it carefully and discovered that it was probably not the head gasket, and sold it to a young Mopar enthusiast in West Virginia. He drove it for a couple of years (it surely went to well over 500k then, and eventually sold it to a collector in Ohio who drove it home without incident.